Concrete

Concrete, which consists of cement, ballast and water, is a fantastic building material and we see it in structures almost everywhere around us. But cement generates high carbon dioxide emissions during production. We want to minimise those emissions.

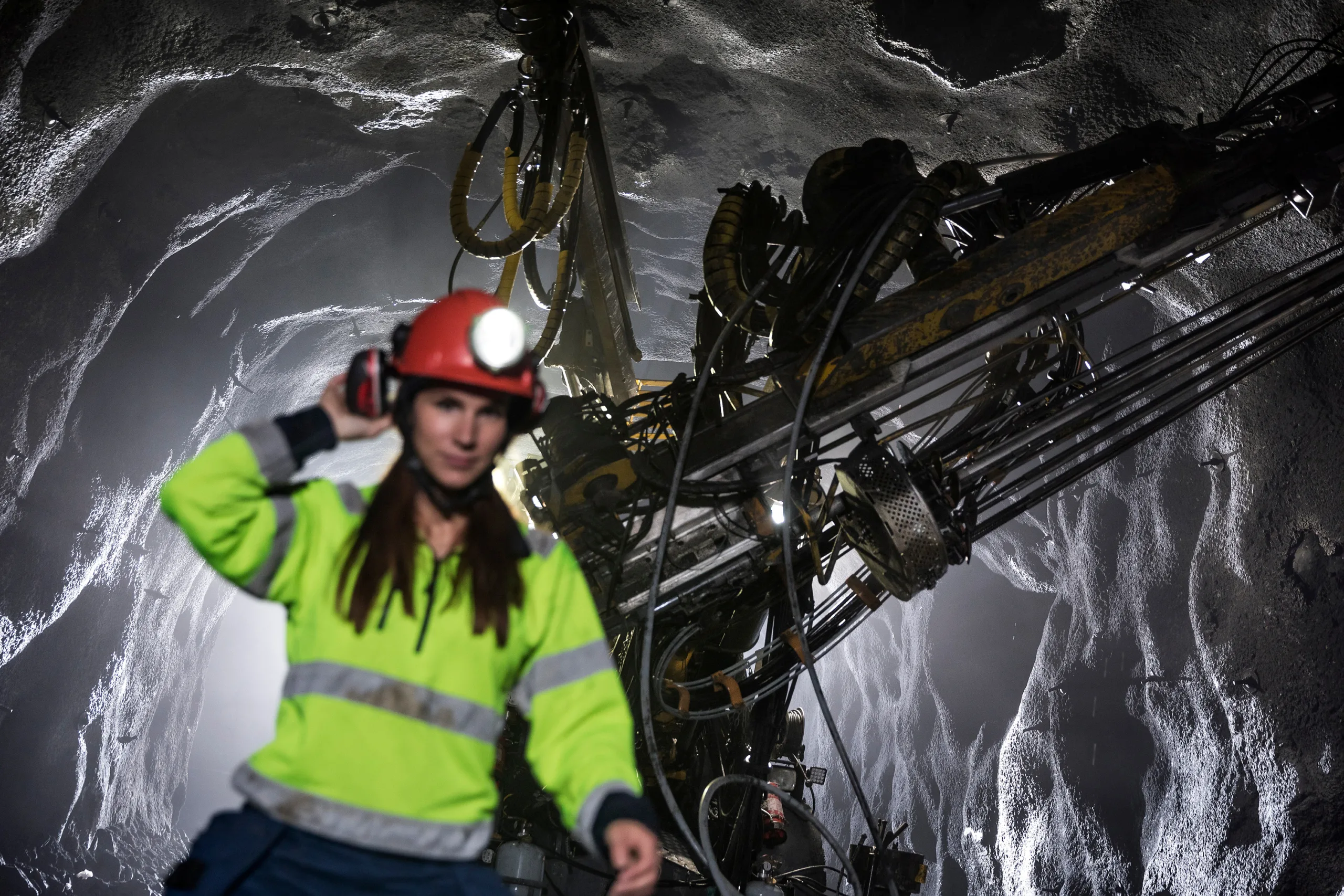

Concrete has been used at least since Roman times and it is an important puzzle piece in the fabric of our civilisation. It is also vital for safety in underground mines. LKAB Berg & Betong has among the highest production capacities in Sweden, with modern factories in Kiruna and Malmberget that utilise waste rock, a residual material from mining. Shotcreting is one of our principal activities, and making use of waste rock this way is smart, efficient and circular. In fact, we are one of the world’s largest producers of shotcrete, a material used for reinforcement in mines, tunnels and rock galleries.

In LKAB’s mines Kiruna and Malmberget we carry out most of the shotcreting and we also do shaft renovation work. Our shotcrete is reinforced with steel fibres, which is also ideal for other applications, such as industrial flooring, since it is highly durable. Fibre in concrete can help to reduce the need for rebar which, in some cases, can be fully replaced, saving both time and material.

Our ultimate ambition is to eliminate the climate impact of the concrete we produce. In the Kiruna mine we have reduced the carbon dioxide emissions from our concrete by 50 tonnes per day by replacing cement in concrete blends with up to 50 percent GGBS – a slag product from steelmaking. We are pleased about these figures. But this is only the beginning.