The future of sublevel caving is being assessed

When mining proceeds at ever greater depth, so do the challenges – rock stresses and costs. However, the latter are but two of several complex issues that must be addressed leading into the future. At the centre of it all is the impact that the mining method, sublevel caving, has on the mine. Therefore, the future of sublevel caving must be carefully considered.

Large-scale sublevel caving, which is employed in both the Kiruna and Malmberget mines, is a resource-efficient and cost-effective method for large-scale underground mining. LKAB has applied this method successfully and efficiently for decades. The method has also been continuously developed and refined to meet the specific requirements of underground mining, for example, enabling greater sublevel slice heights. But there are also a number of challenges associated with large-scale sublevel caving.

“We already have to take active measures with respect to mining towards the main level, at a depth of 1,365 metres, all within the framework off safety and efficiency,” says Matthias Wimmer, section manager at KGE, at LKAB in Kiruna.

Although sublevel caving is a method that allows plenty of scope, flexibility and relatively high ore yield, its complexity increases as the mining depth increases. Essentially, as mining is done vertically, the rock stresses – which, although they can be controlled but never eliminated – find their way to ever greater depths in the mine. This also means that the rock stresses increase in magnitude and that the burden on the main level and infrastructure increases.

“We have to look at how large-scale sublevel caving can be applied in the future – for several reasons. An important aspect is the relationship between mining volumes and mining depth, where great depth in relation to large volume implies greater energy storage in the rock mass,” explains Matthias Wimmer, continuing, “In light of the challenges we face, now and in the future, we must review our strategy carefully and conduct extensive analyses in order to be able to make the right decisions in the short and longer term.”

This is also why Allan Moss, a mining veteran with more than 45 years of experience of, among other methods, caving, has been consulted.

“Allan Moss has considerable experience and knowledge of caving, and has worked in some of the largest caving mines and sat on numerous technical review committees. Allan Moss’s work and input will be an important contribution that will support coming decisions related to sublevel caving in our mines,” says Matthias Wimmer.

The future of caving

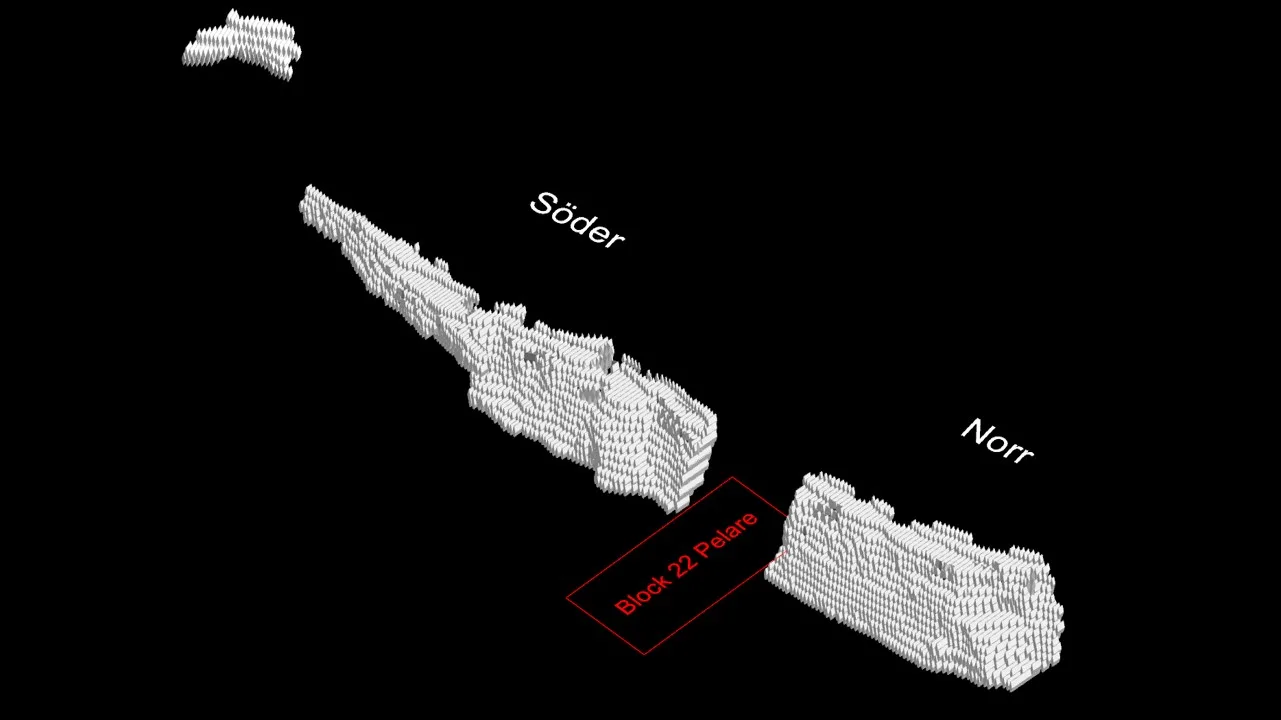

How large-scale sublevel caving will proceed must be thoroughly investigated. One of several possible routes is the establishment of more energy-bearing pillars in the mining areas, similar to the pillar that was established in Block 22 and has effectively divided the mine in two, though at a smaller scale.

“I have worked with mines that have faced similar problems, but conditions vary. This is always the case with mines,” says Alan Moss, president of Sonal Mining Technology, a company specialising in technical solutions for underground mining. Over a period of six months Allan Moss will carry out extensive strategic work and analyses that will subsequently provide a basis for future decisions. This study will be presented in December.

“Mine depth is never forgiving, and a production-based mining plan becomes increasingly problematic at greater depth. Greater depth necessitates greater planning, where more parameters are taken into consideration. This is decisive for how mining is planned and carried out. Quite simply, there are fewer openings for flexibility,” explains Allan Moss.

But, as to the question of possible routes for the Kiruna mine, it is as yet too soon to propose a definitive way forward. Major investigative work remains to be done and several important aspects must be considered.

“LKAB has the most well-trained workforce I have encountered. It’s impressive. The rock mass is also the hardest I’ve seen, and that will have a bearing on the future, because the rock dictates the conditions for future mining,” says Allan Moss.

While the future of the method currently used has to be assessed, all doors to alternative mining methods must remain open. The transition from one method to another is an extensive and relatively long process, about ten years or more.

“It’s too early to talk about possible future mining volumes, though I can say at this point in time that we will need to work with the behaviour surrounding how mining proceeds. To plan mining and to mine according to that plan is fundamental, and it has a lot to do with a behaviour shift,” says Allan Moss.

The strategic plan sets out the conditions for large-scale sublevel caving towards the main level at 1,365 metres, which modifications will need to be made and whether sequencing should be reviewed. Quite simply, it has to do with new and alternative solutions for addressing challenges at depth.

“In summary, the task is to look very carefully at design and processes for safe and efficient mining towards level 1365. In the next phase we will consider possible methods that could be used in the future mine,” says Matthias Wimmer.

“A central part of this work is to broaden our knowledge of the orebody and the rock mass, becausethe rock determines the prerequisites for future mining,” concludes Allan Moss.

Read more about measures for safer and more efficient mining