The green transition starts here

Environmental permit for Gällivare

It's in Gällivare our transformation and the biggest industrial investment ever in Sweden is launching. Here we're looking to develop a sustainable industry.

We've been here for more than 130 years – now the key to LKAB's future lies here, as Gällivare takes the lead in the transformation.

Today, we mine iron ore in about half of the twenty ore bodies in the Malmberget mine. Currently, we have identified mineral resources and mineral reserves of some 5.7 billion tonnes, which gives us the potential to continue operations and be an important player in our community for a long, long time to come.

And the transformation that begins in Gällivare is not only important for LKAB, but an important milestone for all of Sweden and globally. Here will be a hub for the transformation of our entire industry; a new environmental permit is crucial for it to become reality. Therefore, the ongoing permit process for our industrial area and the new demonstration plant is of utmost importance to enable a more sustainable future for LKAB.

in turnover 2022.

of finished product was produced in 2022.

employees in Gällivare/Malmberget.

This is the permit application

In the spring of 2023 LKAB submitted the historic permit application for the operations in Gällivare. It includes a permission to continue the already existing mining and processing operations as well as the construction of a first demonstration plant for fossil-free sponge iron and an apatite plant.

The application involves production of the same quantities of iron ore as today, but with certain expansions and changes such as new landfills and expansion of the tailings dam. As for the mining, a somewhat increased number of iron ore bodies may be in question, but the application does not include a new main level, which will remain at a depth of 1,250 meters.

An increase of production in the processing plant will happen gradually, with new possible facilities, for example a new sorting plant, being placed within the current industrial area.

Demonstration facility and apatite plant

The most striking feature of the permit application is the construction of a demonstration plant for fossil-free sponge iron using HYBRIT technology. This first plant is supposed to produce approximately 1-1.5 million tonnes of sponge iron annually, and is the first step towards completely transforming the Gällivare operations.

In a new facility, we’ll be looking to extract apatite from residual material out of the processing plants. Instead of treating it as waste, like we do today, we’ll move towards the production of phosphorus for mineral fertiliser, rare earth elements, and fluorine. The idea is to produce an apatite concentrate here in Gällivare, which is then transported to the planned industrial park in Luleå for further procecssing.

LKAB's future competitiveness and our opportunity to succeed in our transformation is based on quicker, more efficient and more predictable permit processes.

To get to that point will require understanding and cooperation with many parties, including authorities, courts, politicians and, not least, the communities where we operate. By working together we achieve success!

Why permits are essential

The world faces major challenges as a result of climate-affecting emissions; 2023 was the warmest year on record. We all need to change how we use our resources to meet it.

Today, we emit about 645,000 tonnes of carbon dioxide annually, which corresponds to approximately four percent of Swedish industry’s total emissions. At the same time, the demand for our products is greater than ever: our metals are needed to build railways, buildings and bridges; our minerals are needed for wind turbines, mobile phones and electric cars.

If the permit application is granted and we succeed in our transformation, we can secure profitability for a long time to come, secure our future in Norrbotten and Gällivare and continue to contribute to creating jobs and building an attractive community, while at the same time contributing to reducing global carbon dioxide emissions by 40-50 million tonnes every year, as much as Sweden’s total emissions of greenhouse gases today.

While today’s mining has a major climate impact, the demand for steel is increasing in the world. China accounts for more than 50 percent of the world’s crude steel production, and although the growth rate has slowed somewhat, the country continues to account for the largest import of iron ore on the seaborne market.

Both Russia and Ukraine are major producers of iron ore and the conflict in the region affects many of our European customers who are partially or completely dependent on supplies from there.

And it’s not only the demand for steel that is increasing: Europe’s need for rare earth elements is increasing at a rapid pace, but at present there is a complete lack of extraction in the EU. Greater self-sufficiency in mineral fertilisers is also a challenge, given its important role in food production and that the EU is currently dependent on imports.

We can contribute to solving this.

"Our application is a decisive factor for us as a company, for Gällivare, for the region, for Sweden and for Europe’s future. We are now in the midst of the biggest transition in LKAB’s history and there is no time to lose. We have an ambitious schedule and it is critical that we and society show that we are together capable of addressing complicated issues, which are often implicit in environmental permit applications, while at the same time hastening the transition."

Jan Moström, President and CEO

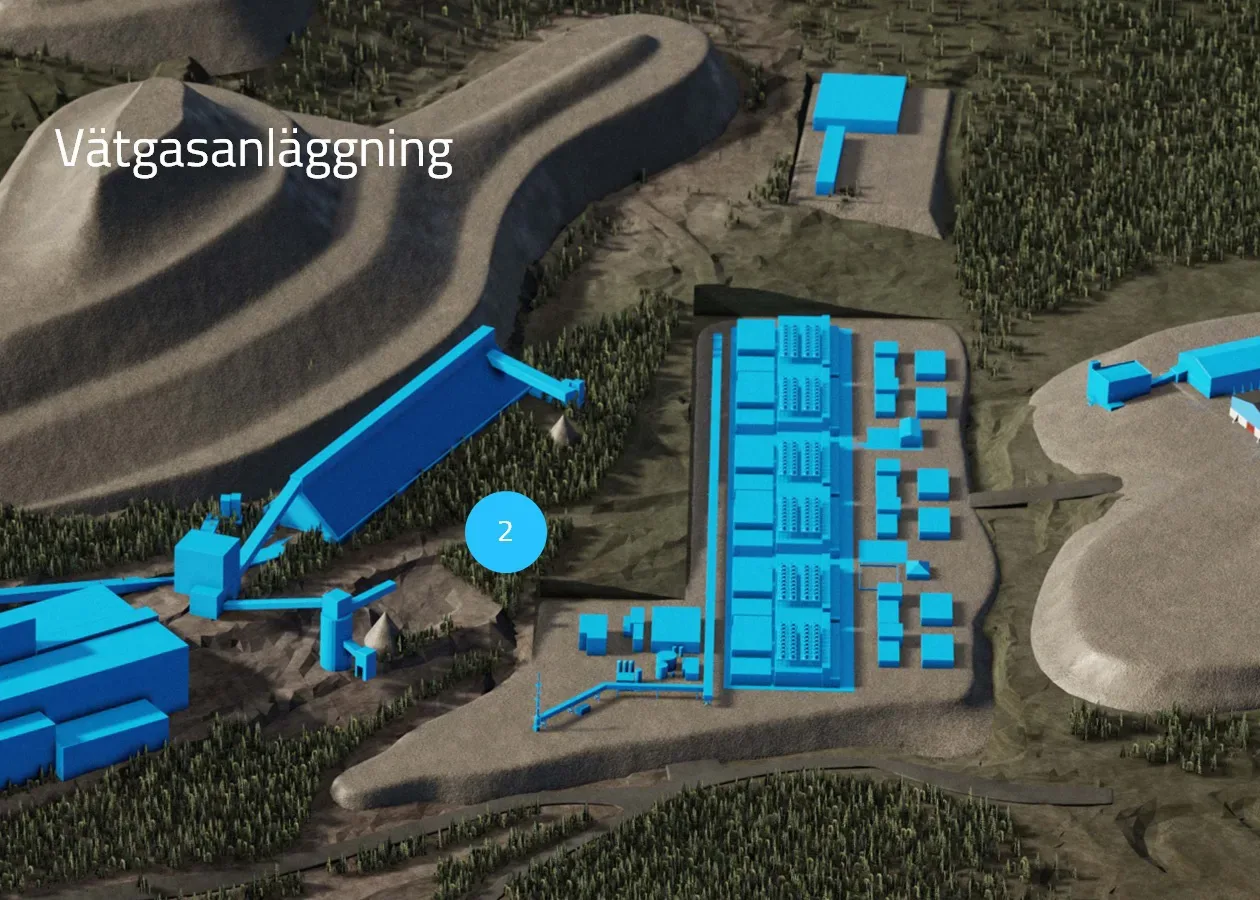

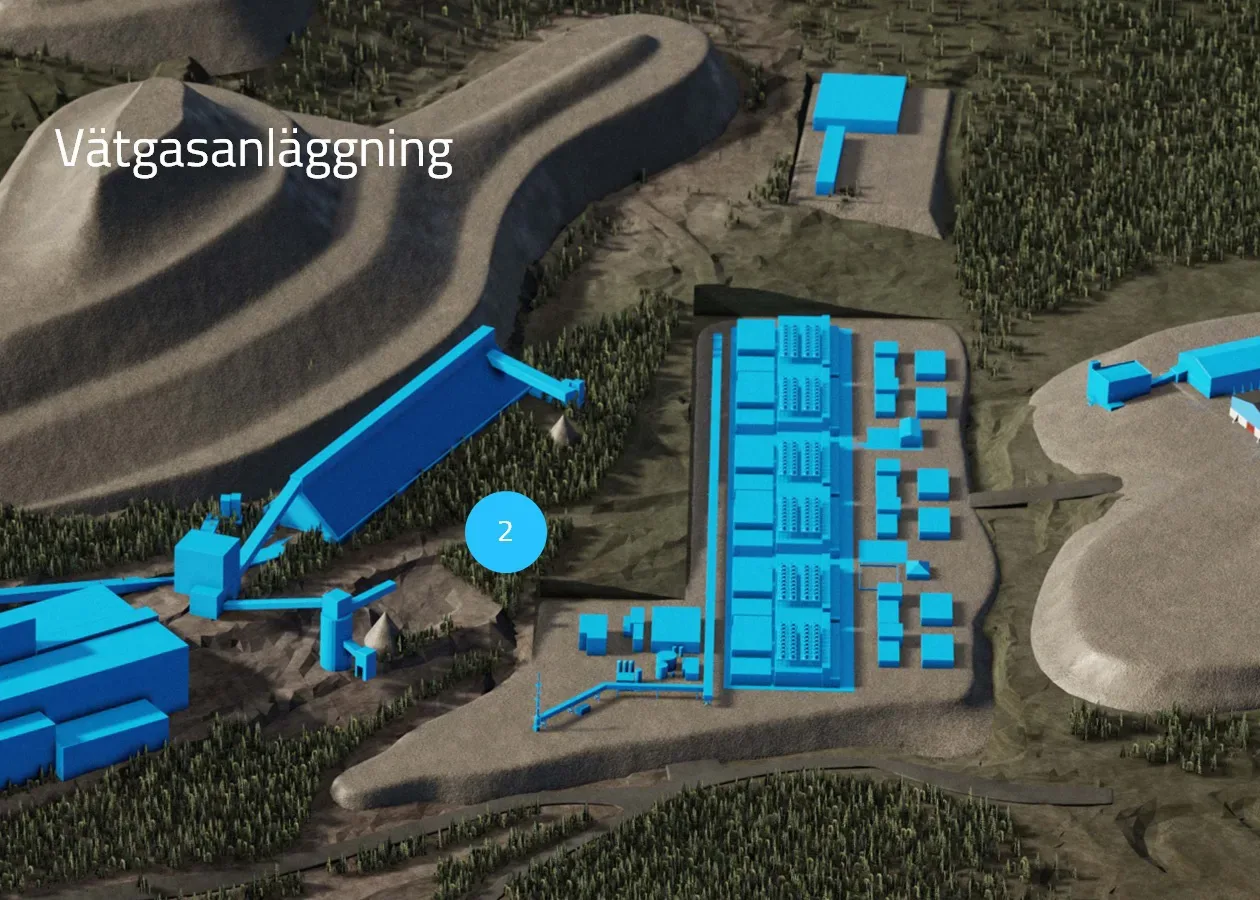

The future industrial area in Malmberget

For LKAB, the transformation means that we set a new world standard for mining at great depths, to produce carbon dioxide-free sponge iron and to extract critical minerals.

This means that we are not only building a new plant for sponge iron, it will require large investments and extensive constructions at our industrial area, as well as in the mine.

Direct reduction plants

This is where the hydrogen-based HYBRIT technology will be used to process our iron ore into carbon dioxide-free sponge iron, which in turn can be used to produce fossil-free steel.

Hydrogen plant

Using fossil-free electricity, we’ll produce hydrogen from water, through a process called electrolysis. This means that water molecules are split into oxygen and hydrogen. The hydrogen can be stored and converted into electricity.

Additives section (dolomite)

When we change our process to start producing direct-reduced iron ore pellets, we need to add dolomite, which is an additive we currently don’t use in Gällivare.

Apatite plant

LKAB’s ore contains apatite, which in turn contains phosphorus and rare earth elements. Today it is mining waste, but that will change. In a first step, the mining waste is refined into apatite concentrate, by constructing an apatite plant directly connected to the iron ore processing.

We're preparing for the transformation

In order to transform the operations in Gällivare, we have already started preparations on the industrial areas. We build, among other things, a new access road, a new mine entrance, a new workshop area and much more.

Challenges to overcome

To achieve our goals, there are significant challenges to overcome, and the permit is just one of them. We need more manpower, new skills and the development of new technology. It will also require a lot of energy – more green electricity – for the production facilities, as well as investments in infrastructure, among other things.