Production of sulphuric acid can reduce demand for purchased energy and provide Luleå with district heat

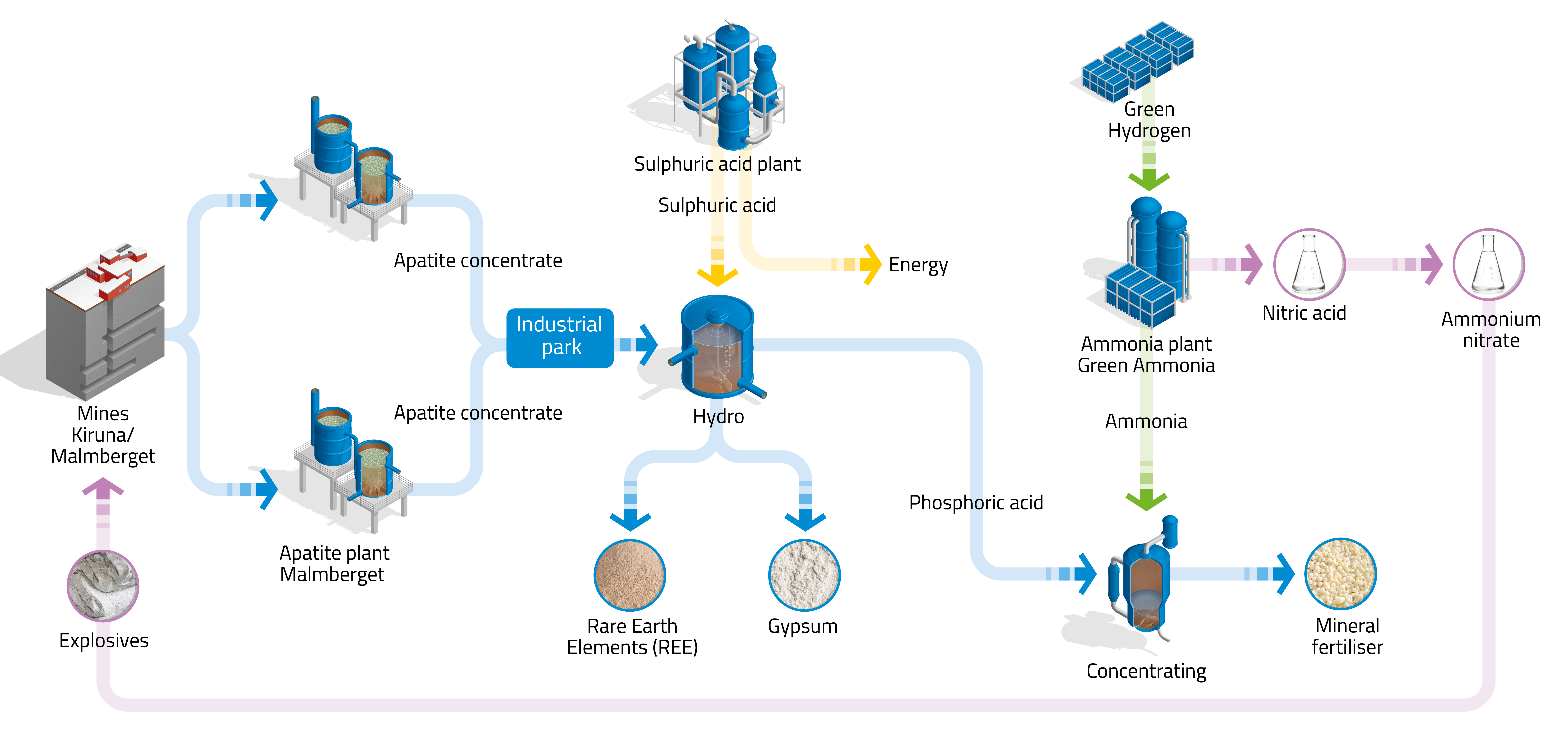

LKAB is planning to develop an industrial park in Luleå, where phosphorus and rare earth elements will be produced from mine waste from iron ore mining. Sulphuric acid is an important input material in this process. Production of sulphuric acid generates large amounts of energy in the form heat and steam, which LKAB intends to use in the production of phosphoric acid and to generate electricity, and thereby reduce the overall demand for purchased energy.

LKAB and Boliden have investigated the possibility of using Boliden’s mine waste from Aitik as an input material for producing sulphuric acid. However, due to increased costs for the planned production, the two companies have come to the joint decision that the financial prerequisites are not in place to continue the collaboration at present.

LKAB has now elected to switch to the standard solution used in the industry; to produce sulphuric acid based on elemental sulphur, which is either extracted from mineral sources or obtained as a byproduct from industrial desulphurisation processes.

“We lose access to the local source and the opportunity to recycle Boliden’s residuals, which was an exciting possibility. In addition to being financially sustainable, our new solution entails improvements in terms of climate, environment and energy efficiency for LKAB’s planned industrial park in Luleå. From a lifecycle perspective, production of sulphuric acid with elemental sulphur generates similar or lower carbon dioxide emissions per tonne sulphuric acid. Furthermore, the need for landfilling and discharge of water used in the processing of pyrite are avoided,” explains Pär Jonsén, Chief Technology Officer at Business Area Special Products at LKAB.

Production of sulphuric acid generates large amounts of energy in the form heat and steam, which LKAB intends to use in the production of phosphoric acid and to generate electricity, and thereby reduce the overall demand for purchased energy.

“This solution can also offer further benefits. It also gives us the possibility of selling and delivering residual energy, for example, as district heating for the residents of Luleå. The amount is directly linked to how much sulphuric acid is produced. LKAB will have the capacity to produce more sulphuric acid that the initial demand,” says Pär.

The switch to an alternative technical solution entails amendments to the environmental impact assessment included in the environmental permit application. In May, LKAB will therefore hold a further consultation meeting and update the application, to be submitted by the close of 2024.