3D virtual mine should provide better support decisions

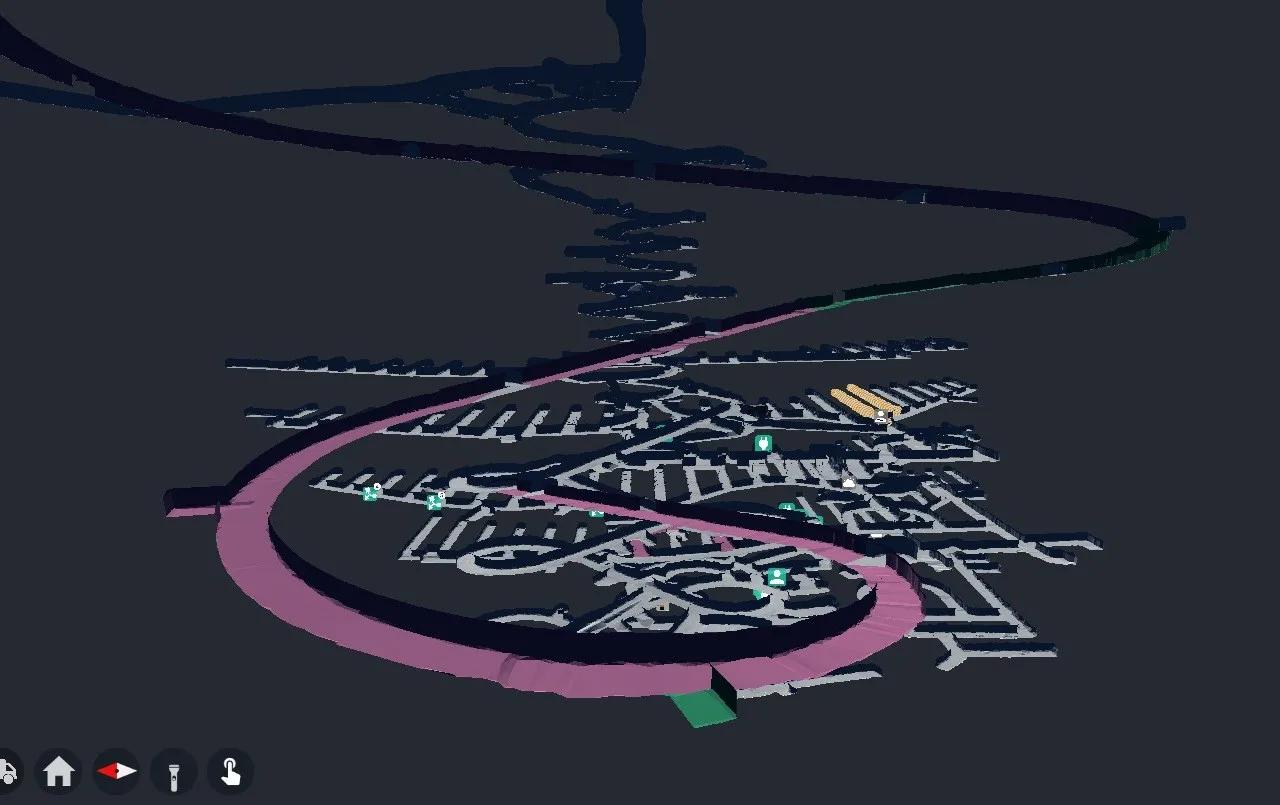

Sharp data from, among other things, the production system, ventilation, water pumps, current mine layout and vehicle positions are fed into a digital three-dimensional copy of the LKAB Konsuln test mine in Kiruna. The goal is to get a current overview that you can easily access from your phone, tablet or computer, in order to facilitate analyzes and decisions.

“We have conducted interviews and behavioural studies to identify how employees work today, what kind of information they use and what they are missing. We started with that as a basis and then continued to build the information view as we went along. The next step is to let the production staff and suppliers of the Konsuln Mine to test the system. Their feedback, combined with qualified future foresights, is driving the work forward,” says Bo Lahti, project manager for virtual mine in the innovation project New World Standard for Sustainable Mining, which LKAB is running together with ABB, Combitech, Epiroc and Sandvik.

Overview and simulation

In addition to a common overview of the mine here and now, the 3D map can also be used to simulate different scenarios where crisis situations have high priority. Of course, this is both easier and cheaper than testing in a real production environment. Where is the nearest rescue chamber, how can we re-route ventilation in the event of a fire, where can I refuel or recharge my car – these are all examples of what can be entered and tested in the 3D model.

Open system platform for rapid progress

The model is built in an open system platform, which means that development is freer and that we can quickly introduce and evaluate new functions. Being independent of a particular system or a specific supplier is an important starting point in the collaborative project for a new world standard for sustainable mining.

“The fact that everyone can see the same thing no matter where you are is one of the cornerstones. By clicking on different filters in the map, you can see different facts. In the long term, we want you to get the information you need to do your job as safely and efficiently as possible, based on your role and function,” says Mikael Winnebäck, project manager at LKAB.

“I see the model a bit like an information board, we get a quick overview of the current situation. If we then need to fix something specific, we go further to the underlying system. Since everyone has access to the same information, it makes it easier to make decisions at the right level,” says Stefan Rova, production manager at LKAB Berg och Betong in Konsulngruvan.

Facts:

- Virtual mining in 3D is referred to internally as SMITE; “Simulated mining idea test environment”.

- The 3D model is under constant development and evaluation takes place continuously through tests in production-like conditions.

- The virtual mine is part of the collaborative project that LKAB is running together with ABB, Epiroc, Combitech and Sandvik to set a new world standard for mining.